APACK PACKAGING TECHNOLOGIES

Türkiye

İmalatçı/ Üretici

APACK PACKAGING TECHNOLOGIES

Türkiye

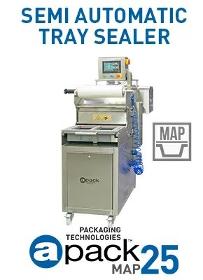

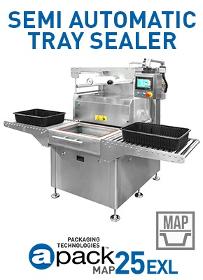

The MAP25 series stands out as the most proficient and dependable among its counterparts. It boasts exceptional durability and does not tend to malfunction, thus preventing operational issues. Moreover, this unit is designed to fit compact production spaces and can be effortlessly cleaned, serviced, and operated. Notably, all models in this series are suitable for packaging food and medical products. Skin packaging methods on plastic tray or paper are new trends in the packaging industry. Although the techniques are similar, they differ based on the packaging material used. Despite their higher cost, these methods offer an effective shelf presentation and are particularly appealing to the new generation. These two methods have been increasingly employed in recent years to showcase the product's shape precisely on store shelves.

Fiyat teklifi isteyin

APACK PACKAGING TECHNOLOGIES

Türkiye

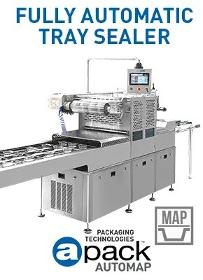

The AUTOMAP series of machines are complete and automated packaging systems that meet all your packaging requirements. These high-capacity autoMAP machines are particularly well-suited to the Food and Medical markets, where quality and precision are paramount. Additionally, these systems are designed to work seamlessly with other machines in your manufacturing facility, providing a cohesive and integrated packaging solution. In fully automated production lines, autoMAP packaging machines play a critical role by providing the ability to package products using various techniques, such as Modified Atmosphere Packaging (MAP) with vacuum and gas and thermal sealing applications. These versatile machines offer various packaging options for different product types and requirements. Production line begins with tray feeding and manages every step of the packaging process, including filling, weighing, sorting, MAP sealing, labeling, collecting, and stacking.

Fiyat teklifi isteyin

APACK PACKAGING TECHNOLOGIES

Türkiye

These machines are fully automatic and can form, fill, and seal formed trays. Depending on the desired package type, they can perform VACUUM, MAP, and SKIN packaging and are suitable for food and medical packaging. Packaging can be fully automated using these machines, from tray production to final product collection. It is also highly flexible and can be easily integrated with different packaging system accessories and machines in the production line. Customization options for the machine elements are available to match the production area and customer's requirements. Various packaging molds can be used, including square, triangle, round, and rectangular shapes. The machines can handle hot and cold filling of products, and packaging methods do not affect the product. Additionally, they can produce cost-effective packaging at high capacities using single or multi-layered, laminated, foam, or medical films.

Fiyat teklifi isteyin

APACK PACKAGING TECHNOLOGIES

Türkiye

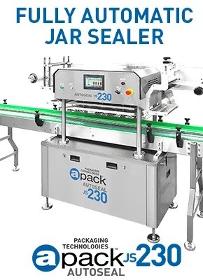

AutoSEAL-JS230 is a sealing machine designed for PET jars containing food or chemical products. It is particularly suited for sealing acidic products, including pickles, olives, and brine, as well as for sealing liquid or granular chemical products. AutoSEAL-JS230 machines are fully automated and use heat treatment to seal PET jars mouth of various sizes with a multi-layer top film, making them suitable for products that do not require a vacuum. These machines are specifically designed for use in small production areas. Unlike ultrasonic sealing systems used in food packaging, the sealing film on jars sealed with the AutoSEAL-JS230 does not break or fall into the product when opened. This model is a reliable, user-friendly solution for packaging pickle, olive, and brine products. The production line starts with stacking empty jars on conveyors and can cover all stages of product filling, weighing, sorting, sealing, capping, labeling, collection, and stacking.

Fiyat teklifi isteyin

APACK PACKAGING TECHNOLOGIES

Türkiye

This solution is ideal for packaging food and medical products that do not necessitate a vacuum or gas. It is commonly employed in packaging various items, including pastries, baked goods, takeout meals, dry foods, pre-made meals, salads, and deli items prepared for daily consumption. Its effectiveness is particularly noteworthy for food products arranged on large markets' shelves for daily sales. The EcoSEAL packaging machine with fully automated systems can meet all your packaging needs. It is designed for tight spaces and limited budgets, similar to the features of fully automated machines. The system is compatible with a range of auxiliary units, including tray feeding, filling, weighing, sorting, sealing, labeling, collecting and stacking equipment. The automation unit responsible for monitoring and inspecting all aspects of the production line will signal warnings in the event of any possible errors, misuse, or installation failures, thereby safeguarding the system.

Fiyat teklifi isteyin

APACK PACKAGING TECHNOLOGIES

Türkiye

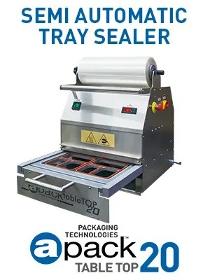

TableTOP20 is powered by standard local electricity, eliminating the need for additional devices, and is an economical option for those not yet ready to invest in fully automated systems. The machine features a changeable mold system that allows easy and quick switching between different types of product packaging. It can accommodate single or multi-compartment trays. Although it does not have a vacuum system, IQF can be applied to achieve extended shelf life. Additionally, it can work with various tray materials such as plastic, aluminum, and laminated paper. The TableTOP20 tray sealing unit is powered by an asynchronous electric motor, enabling it to deliver faster, higher quality, and stronger seals compared to manual sealing in other desktop machines. The digital control systems fix the sealing temperature and time at the desired parameters, resulting in a perfect-looking product that is suitable for both hot and cold packaging.

Fiyat teklifi isteyin

APACK PACKAGING TECHNOLOGIES

Türkiye

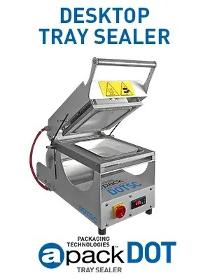

DOTS and DOTSC are cost-effective tray-sealing machines ideal for market testing new products, low-volume production, or hot/cold ready-to-eat food delivery. The DOT series machines are designed to use both flexible top film with plastic tray (DOTSC) and laminated paper caps with laminated paper tray (DOTS). They are easy to use, carry, and operate without any complications. With its compact structure, the DOT series is ideal for small-scale food packaging, as it does not take up much space. The DOT Desktop Tray Sealers have international certifications, ensuring the quality of the product. Additionally, the machine temperature does not affect the packaged product during sealing. Single and multi-compartment trays are compatible with DOT series machines and can handle both hot and cold products. IQF application ensures a long shelf life for the packaged products. With a capacity of producing up to 2000 packages per day with a single operator.

Fiyat teklifi isteyin

APACK PACKAGING TECHNOLOGIES

Türkiye

Tailored to meet your non-standard large and heavy MAP packaging needs, this unit features various engineering modifications explicitly designed for large and heavy packaging requirements while retaining the basic functionalities of the MAP25 series. The unit is particularly suitable for packaging products prone to spilling, emitting odors, containing oil, or polluting the packaging environment such as fish. To facilitate easy cleaning, the drawer pool is designed to be washable. The sealing pool is equipped with a lift to facilitate the processing of heavy packages, while the unit comes with a standard free roller inlet and outlet conveyors.

Fiyat teklifi isteyin

APACK PACKAGING TECHNOLOGIES

Türkiye

If you require increased production capacity but lack the budget to upgrade to a fully automatic system, our Map25DS Double Station model is ideal. Incorporating two stations on a single body, the MAP25DS enhances production capacity without incurring high costs. The MAP25DS is designed for dual personnel operation, delivering twice the performance of a single machine. Our DS model features all the capabilities of the MAP25, and it accommodates both plastic and laminated paper trays. Additionally, the unit supports using multi-layered printed/non-printed top film or laminated paper lids.

Fiyat teklifi isteyin

APACK PACKAGING TECHNOLOGIES

Türkiye

Skin packaging methods on plastic tray or paper are new trends in the packaging industry. Although the techniques are similar, they differ based on the packaging material used. These two methods have been increasingly employed in recent years to showcase the product's shape precisely on store shelves. In the another type of the SKIN technology is uses flat, borderless laminated paper plates instead of plastic trays, named CARDBOARD. The cardboard can be printed with a desired graphic design, which can be visually appealing to consumers. This type of packaging can be displayed on shelves or hung up. Similarly to skin packaging, cardboard packaging is often used for portioned products, and the borderless form allows the product's shape to be fully discrete. APACK machines are capable of packaging SKIN technology in both TRAY and CARDBOARD with MAP25, autoMAP and perFORMA Thermoform series.

Fiyat teklifi isteyinİmalatçı/ Üretici

Ferhatpasa Mahallesi 22. Sokak No:43 Atasehir/Istanbul

34888 Istanbul - Türkiye

europages aynı zamanda size bunları da öneriyor

Faaliyete yakın işletmelerin seçimi:

İlginizi çekebilecek seçme ürünler

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Türkiye

Portanar Yarı Otomatik portakal sıkma makineleri; restoran, otel, eğlence ve alışveriş merkezleri, yurtlar, üniversiteler, büfeler gibi mekânlarda portakal, mandalina, greyfurt, limon gibi meyvelerin suyunun çıkarılması amacıyla tasarlanmıştır. Makinanın çalıştırılması ile otomatik olarak besleme, kesme ve sıkma işlemlerini yapar. Kullanımı çok kolaydır. Hijyenik ve güvenlikli bir makinadır. • Dakikada 28 adet portakal sıkma kapasitesi • Çapı 65mm ile 80 mm arası olan meyveleri sıkma imkanı. • Meyve haznesinde 7 kg portakal depolama imkanı • 15 kg lık meyve posası biriktirme kovası • Meyve yolluğunda 6 ila 8 portakal depolama imkanı • Kapak çıkarıldığında sıkmayı durduran güvenlik switchi • Kolay sökülüp takılabilen, bulaşık makinesinde yıkanabilir (Kapak hariç) aparatlar. • Meyve posasını süzen, gıda standartlarına uygun süzgeç ve süzgeç tablası • Paslanmaz gövde • Paslanmaz damlalık • Silikon kılıflı açma kapama düğmesi

Fiyat teklifi isteyin

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Türkiye

Ürün Özellikleri: %100 yerli üründür. Ateş üstünde ızgara keyfi, Yaktığınız ateş ile çay keyfinize devam edin, Yemek yapın, Barbekü olarak kullanın, Çok yönlü kullanımıyla kamplarınıza keyif katın. Katlanır, az yer kaplar. Taşıma çantası ile rahatlıkla taşıyabilirsiniz. Paket içeriği: Taşıma çantası ile birlikte TEKNİK ÖZELLİKLER 1) Genişlik 58,5cm 2) Derinlik 27,5cm 3) Yükseklik 22cm 4) Ağırlık: 2,4 Kg

Fiyat teklifi isteyin

CROMMAC MAKINA METAL IMALAT SANAYI VE TICARET LIMITED SIRKETI

Türkiye

Ananas Soyma makineleri; restoran, otel, eğlence ve alışveriş merkezleri, yurtlar, üniversiteler, büfeler, manav tezgahları gibi mekânlarda, çok fazla güç gerektirmeden meyveyi kabuğundan ve çekirdeğinden ayırmak için dizayn edilmiştir. Sökülüp takılabilen 304 kalite paslanmaz bıçak sayesinde hijyenik ve güvenlikli bir makinadır. Ayrıca piston sayesinde kesme işlemi bittikten sonra otomatik olarak kol yukarı kalmaktadır. Kullanımı çok kolaydır.

Fiyat teklifi isteyin

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Türkiye

Ananas Soyma Makineleri; Restoran, otel, eğlence ve alışveriş merkezleri, yurtlar, üniversiteler, büfeler, manavlar, tezgahlar, gibi mekânlarda çok fazla güç gerektirmeden meyveyi kabuğundan ve çekirdeğinden ayırmak için dizayn edilmiştir. Sökülüp takılabilen 304 kalite paslanmaz bıçak sayesinde hijyenik ve güvenlikli bir makinadır. Kullanılan Piston sayesinde kesme ve kesim sonrası çok fazla güç gerektirmeden kolun havaya kalkması sağlanmıştır. . Deneme Yapılmış Ürünlerin Geri İadesi Kabul Edilmemektedir.1 Yıl garantilidir.

Fiyat teklifi isteyinFiyat Teklifi Talebi

Tek bir talep oluşturun ve doğrulanmış tedarikçilerden birden fazla teklif alın.

- Yalnızca ilgili tedarikçiler

- Veri gizliliği uyumlu

- 100% ücretsiz