- europages

- >

- ŞİRKETLER - TEDARİKÇİLER - YÜKÜMLÜLER

- >

- air it

Sonuçlar

Air it - Ithalat/Ihracat

SERAL TEKSTIL EV VE OTEL TEKSTIL A.S.

Türkiye

Pillow and quiilts with special air canals, circulates the air during sleepand distribute heat homogeneously by performing inside air emission. Meanwhile, it prevents adour formation. The fabric is soft, breathable and quickly absorbs moisture from the skin outward.

Fiyat teklifi isteyin

MEDISAM MEDIKAL CONSTRUCTION HEALTH SYSTEMS LTD. STI

Türkiye

You can choose the type and volume of the production system that suits your needs and application area’s specifications and customize the requested system according to your needs. OXY World PSA Oxygen Production system consists of a compressor, an air tank, a dryer, an oxygen generator, and an oxygen tank. The air, taken from the environment through the compressor, is stored in the air tank. The moisture in the air that passes from the air tank to the dryer is separated, this air is filtered in the active carbon tower, and dry air is delivered to the oxygen generator to obtain oxygen. When the dry air reaches the oxygen generator, it is separated through Zeolite and transformed into pure oxygen. Medisam Healthcare Systems, with its extensive experience spanning many years, advanced technical equipment, and a workforce of experts in the field, can manufacture oxygen systems of different specifications and sizes tailored to your hospital’s needs.

Fiyat teklifi isteyin

EKOTEC ENERGY

Türkiye

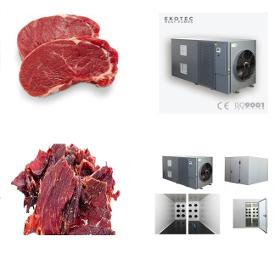

Explanation: The Fruit and Vegetables drying heat pump: is produced for the manufacturers in the food drying sector but because of its functional structure the type of drying is followed by the carpet cleaning factories. With the use of heat pump technology in the drying sector, it has become one of the drying methods with increasing efficiency. The food desiccant heat pump takes some of its energy from the air as it is in the air source heat pumps, and takes a part of it from the electric energy. The fruit and vegetable desiccant heat pump is placed inside the fully insulated drying chamber and the inside of the drying chamber is 65 ° C, allowing the water to evaporate in the fruit, vegetable, or other food products. The evaporator water is carried to the heat pump by means of fans, and the liquid is thrown out by making it liquid. In this way, the drying process is completed.

Fiyat teklifi isteyin

EKOTEC ENERGY

Türkiye

Explanation: The Fruit and Vegetables drying heat pump: is produced for the manufacturers in the food drying sector but because of its functional structure the type of drying is followed by the carpet cleaning factories. With the use of heat pump technology in the drying sector, it has become one of the drying methods with increasing efficiency. The food desiccant heat pump takes some of its energy from the air as it is in the air source heat pumps, and takes a part of it from the electric energy. The fruit and vegetable desiccant heat pump is placed inside the fully insulated drying chamber and the inside of the drying chamber is 65 ° C, allowing the water to evaporate in the fruit, vegetable or other food products. The evaporator water is carried to the heat pump by means of fans, and the liquid is thrown out by making it liquid. In this way, the drying process is completed.

Fiyat teklifi isteyin

EKOTEC ENERGY

Türkiye

Explanation: The Fruit and Vegetables drying heat pump: is produced for the manufacturers in the food drying sector but because of its functional structure the type of drying is followed by the carpet cleaning factories. With the use of heat pump technology in the drying sector, it has become one of the drying methods with increasing efficiency. The food desiccant heat pump takes some of its energy from the air as it is in the air source heat pumps, and takes a part of it from the electric energy. The fruit and vegetable desiccant heat pump is placed inside the fully insulated drying chamber and the inside of the drying chamber is 65 ° C, allowing the water to evaporate in the fruit, vegetable or other food products. The evaporator water is carried to the heat pump by means of fans, and the liquid is thrown out by making it liquid. In this way, the drying process is completed.

Fiyat teklifi isteyin

EKOTEC ENERGY

Türkiye

The Fruit and Vegetables drying heat pump: is produced for the manufacturers in the food drying sector but because of its functional structure the type of drying is followed by the carpet cleaning factories. With the use of heat pump technology in the drying sector, it has become one of the drying methods with increasing efficiency. The food desiccant heat pump takes some of its energy from the air as it is in the air source heat pumps, and takes a part of it from the electric energy. The fruit and vegetable desiccant heat pump is placed inside the fully insulated drying chamber and the inside of the drying chamber is 65 ° C, allowing the water to evaporate in the fruit, vegetable, or other food products. The evaporator water is carried to the heat pump by means of fans, and the liquid is thrown out by making it liquid. In this way, the drying process is completed.

Fiyat teklifi isteyin

EKOTEC ENERGY

Türkiye

Explanation: The Fruit and Vegetables drying heat pump: is produced for the manufacturers in the food drying sector but because of its functional structure the type of drying is followed by the carpet cleaning factories. With the use of heat pump technology in the drying sector, it has become one of the drying methods with increasing efficiency. The food desiccant heat pump takes some of its energy from the air as it is in the air source heat pumps, and takes a part of it from the electric energy. The fruit and vegetable desiccant heat pump is placed inside the fully insulated drying chamber and the inside of the drying chamber is 65 ° C, allowing the water to evaporate in the fruit, vegetable or other food products. The evaporator water is carried to the heat pump by means of fans, and the liquid is thrown out by making it liquid. In this way, the drying process is completed.

Fiyat teklifi isteyin

EKOTEC ENERGY

Türkiye

The Fruit and Vegetables drying heat pump: is produced for the manufacturers in the food drying sector but because of its functional structure the type of drying is followed by the carpet cleaning factories. With the use of heat pump technology in the drying sector, it has become one of the drying methods with increasing efficiency. The food desiccant heat pump takes some of its energy from the air as it is in the air source heat pumps, and takes a part of it from the electric energy. The fruit and vegetable desiccant heat pump is placed inside the fully insulated drying chamber and the inside of the drying chamber is 65 ° C, allowing the water to evaporate in the fruit, vegetable or other food products. The evaporator water is carried to the heat pump by means of fans, and the liquid is thrown out by making it liquid. In this way, the drying process is completed.

Fiyat teklifi isteyin

EKOTEC ENERGY

Türkiye

Explanation: The Fruit and Vegetables drying heat pump: is produced for the manufacturers in the food drying sector but because of its functional structure the type of drying is followed by the carpet cleaning factories. With the use of heat pump technology in the drying sector, it has become one of the drying methods with increasing efficiency. The food desiccant heat pump takes some of its energy from the air as it is in the air source heat pumps, and takes a part of it from the electric energy. The fruit and vegetable desiccant heat pump is placed inside the fully insulated drying chamber and the inside of the drying chamber is 65 ° C, allowing the water to evaporate in the fruit, vegetable, or other food products. The evaporator water is carried to the heat pump by means of fans, and the liquid is thrown out by making it liquid. In this way, the drying process is completed.

Fiyat teklifi isteyin

EKOTEC ENERGY

Türkiye

Explanation: The Fruit and Vegetables drying heat pump: is produced for the manufacturers in the food drying sector but because of its functional structure the type of drying is followed by the carpet cleaning factories. With the use of heat pump technology in the drying sector, it has become one of the drying methods with increasing efficiency. The food desiccant heat pump takes some of its energy from the air as it is in the air source heat pumps, and takes a part of it from the electric energy. The fruit and vegetable desiccant heat pump is placed inside the fully insulated drying chamber and the inside of the drying chamber is 65 ° C, allowing the water to evaporate in the fruit, vegetable or other food products. The evaporator water is carried to the heat pump by means of fans, and the liquid is thrown out by making it liquid. In this way, the drying process is completed.

Fiyat teklifi isteyin

EKOTEC ENERJI ITH.IHR. PAZ.SAN. VE TIC. LTD. STI

Türkiye

The Fruit and Vegetables drying heat pump: is produced for the manufacturers in the food drying sector but because of its functional structure the type of drying is followed by the carpet cleaning factories. With the use of heat pump technology in the drying sector, it has become one of the drying methods with increasing efficiency. The food desiccant heat pump takes some of its energy from the air as it is in the air source heat pumps, and takes a part of it from the electric energy. The fruit and vegetable desiccant heat pump is placed inside the fully insulated drying chamber and the inside of the drying chamber is 65 ° C, allowing the water to evaporate in the fruit, vegetable, or other food products. The evaporator water is carried to the heat pump by means of fans, and the liquid is thrown out by making it liquid. In this way, the drying process is completed.

Fiyat teklifi isteyin

EKOTEC ENERJI ITH.IHR. PAZ.SAN. VE TIC. LTD. STI

Türkiye

Explanation: The Fruit and Vegetables drying heat pump: is produced for the manufacturers in the food drying sector but because of its functional structure the type of drying is followed by the carpet cleaning factories. With the use of heat pump technology in the drying sector, it has become one of the drying methods with increasing efficiency. The food desiccant heat pump takes some of its energy from the air as it is in the air source heat pumps, and takes a part of it from the electric energy. The fruit and vegetable desiccant heat pump is placed inside the fully insulated drying chamber and the inside of the drying chamber is 65 ° C, allowing the water to evaporate in the fruit, vegetable, or other food products. The evaporator water is carried to the heat pump by means of fans, and the liquid is thrown out by making it liquid. In this way, the drying process is completed.

Fiyat teklifi isteyin

EKOTEC ENERJI ITH.IHR. PAZ.SAN. VE TIC. LTD. STI

Türkiye

Explanation: The Fruit and Vegetables drying heat pump: is produced for the manufacturers in the food drying sector but because of its functional structure the type of drying is followed by the carpet cleaning factories. With the use of heat pump technology in the drying sector, it has become one of the drying methods with increasing efficiency. The food desiccant heat pump takes some of its energy from the air as it is in the air source heat pumps, and takes a part of it from the electric energy. The fruit and vegetable desiccant heat pump is placed inside the fully insulated drying chamber and the inside of the drying chamber is 65 ° C, allowing the water to evaporate in the fruit, vegetable, or other food products. The evaporator water is carried to the heat pump by means of fans, and the liquid is thrown out by making it liquid. In this way, the drying process is completed.

Fiyat teklifi isteyin

EKOTEC ENERJI ITH.IHR. PAZ.SAN. VE TIC. LTD. STI

Türkiye

The Fruit and Vegetables drying heat pump: is produced for the manufacturers in the food drying sector but because of its functional structure the type of drying is followed by the carpet cleaning factories. With the use of heat pump technology in the drying sector, it has become one of the drying methods with increasing efficiency. The food desiccant heat pump takes some of its energy from the air as it is in the air source heat pumps, and takes a part of it from the electric energy. The fruit and vegetable desiccant heat pump is placed inside the fully insulated drying chamber and the inside of the drying chamber is 65 ° C, allowing the water to evaporate in the fruit, vegetable, or other food products. The evaporator water is carried to the heat pump by means of fans, and the liquid is thrown out by making it liquid. In this way, the drying process is completed.

Fiyat teklifi isteyin

EKOTEC ENERJI ITH.IHR. PAZ.SAN. VE TIC. LTD. STI

Türkiye

Explanation: The Fruit and Vegetables drying heat pump: is produced for the manufacturers in the food drying sector but because of its functional structure the type of drying is followed by the carpet cleaning factories. With the use of heat pump technology in the drying sector, it has become one of the drying methods with increasing efficiency. The food desiccant heat pump takes some of its energy from the air as it is in the air source heat pumps, and takes a part of it from the electric energy. The fruit and vegetable desiccant heat pump is placed inside the fully insulated drying chamber and the inside of the drying chamber is 65 ° C, allowing the water to evaporate in the fruit, vegetable or other food products. The evaporator water is carried to the heat pump by means of fans, and the liquid is thrown out by making it liquid. In this way, the drying process is completed.

Fiyat teklifi isteyin

EKOTEC ENERJI ITH.IHR. PAZ.SAN. VE TIC. LTD. STI

Türkiye

The Fruit and Vegetables drying heat pump: is produced for the manufacturers in the food drying sector but because of its functional structure the type of drying is followed by the carpet cleaning factories. With the use of heat pump technology in the drying sector, it has become one of the drying methods with increasing efficiency. The food desiccant heat pump takes some of its energy from the air as it is in the air source heat pumps, and takes a part of it from the electric energy. The fruit and vegetable desiccant heat pump is placed inside the fully insulated drying chamber and the inside of the drying chamber is 65 ° C, allowing the water to evaporate in the fruit, vegetable or other food products. The evaporator water is carried to the heat pump by means of fans, and the liquid is thrown out by making it liquid. In this way, the drying process is completed.

Fiyat teklifi isteyin

EKOTEC ENERJI ITH.IHR. PAZ.SAN. VE TIC. LTD. STI

Türkiye

The Fruit and Vegetables drying heat pump: is produced for the manufacturers in the food drying sector but because of its functional structure the type of drying is followed by the carpet cleaning factories. With the use of heat pump technology in the drying sector, it has become one of the drying methods with increasing efficiency. The food desiccant heat pump takes some of its energy from the air as it is in the air source heat pumps, and takes a part of it from the electric energy. The fruit and vegetable desiccant heat pump is placed inside the fully insulated drying chamber and the inside of the drying chamber is 65 ° C, allowing the water to evaporate in the fruit, vegetable or other food products. The evaporator water is carried to the heat pump by means of fans, and the liquid is thrown out by making it liquid. In this way, the drying process is completed.

Fiyat teklifi isteyinBenzer ürünler mi satıyorsunuz veya üretiyorsunuz?

europages'a üye olun ve ürünlerinizi sergileyin

ETI SODA

Türkiye

Potassium hydroxide Potassium hydroxide is a common inorganic base with a chemical formula of KOH and a molecular weight of 56.1. White powder or flake solid, melting point 380 ℃, boiling point 1324 ℃, relative density 2.04 g/cm3, refractive index n20/D 1.421, vapor pressure 1mmHg (719 ℃). Its properties are similar to sodium hydroxide, which is strongly alkaline and corrosive. The pH of a 0.1 mol/L solution is 13.5. Easily absorb moisture in the air and deliquescence, absorbing carbon dioxide to form potassium carbonate. Physical properties: white flakes, granules, shiny, color allowed, hygroscopic, soluble in Chemical properties: Melting point 318.4 ℃ Boiling point 1390 ℃ The relative density of Solubility: soluble in water, and strongly exothermic. Dissolved in ethanol and glycerol easily; insoluble in acetone, ether. Exposed on the air, it will eventually completely dissolved into solution.chemical caustic soda flakes manufacturers in Turkey

Fiyat teklifi isteyin

KARATEK IC VE DIS TICARET LTD STI

Türkiye

Special Features of Tenera Lady Pads Perforated Top Sheet Transfers the Liquid Immediatly isinside the Pad. Distrubution Layer Takes away and distrubutes the coming liquid through the absorbation core of the pad and makes you feel dry. Super Absorbent Core Converts the Coming Liquid into gel and blocks, helps reducing the odour. Breathable Outer Layer It Keeps the air circulation through it micro holes in order to let skin breath.

Fiyat teklifi isteyin

MIOFLEX INDUSTRIAL HOSES, PNEUMATIC AND HYDROLIC FITTINGS FACTORY

Türkiye

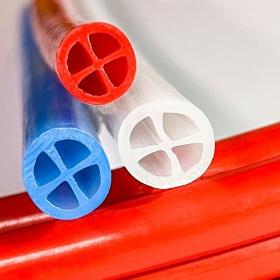

They are pneumatic equipment required for the transmission of compressed air. It varies depending on the conditions of the air passing through it and the conditions of the environment in which it will operate. There are varieties such as polyurethane, polyethylene, teflon and polyamide. Pneumatic hoses, which come in a variety of colors, are also sold in spiral form, ready to be connected to moving locations. Pneumatic hoses must be compatible with pneumatic connection equipment. It is important to comply with the measurement tolerances for these products. Product features: DIAMETER: 8-16mm. LENGTH: 50- 100 meters. OPERATING TEMPERATURE: 23°C - 70°C WORKING PRESSURE: 11-18 bar

Fiyat teklifi isteyinSonuçlar

Air it - Ithalat/IhracatSonuç sayısı

21 ÜrünlerÜlkeler

Firma tipine

Kategoriye

- Endüstriyel kurutucular/kurutma makineleri (8)

- Endüstriyel ısı pompaları (4)

- Enerji - yenilenebilir (3)

- Dondurulmuş kuru etler (1)

- Gıda - makineler ve ekipmanlar (1)

- Hijyen/Sağlık ve güzellik - Ürünler (1)

- Kurutulmuş etler (1)

- Kurutulmuş sebzeler (1)

- Medikal/tıbbi amaçlı gaz - Ekipman ve cihazlar (1)

- Nitrojen / Azot (1)

- Plastik hortumlar, borular ve tüpler (1)

- Tekstil - İthalat/İhracat (1)

- Zeytin (1)

- İthalat-İhracat - kimyasallar ve eczacılık ürünleri (1)

- İthalat/İhracat - Gıda ve Tarım (1)